Oilfield Production – With Infographic!

At Plainsman Manufacturing Inc., we manufacture and distribute products for oilfield production, pipeline maintenance, construction, gas, and water distribution. We are always looking out for new and better products and services to meet our customer’s requirements and the changing demands of the industry.

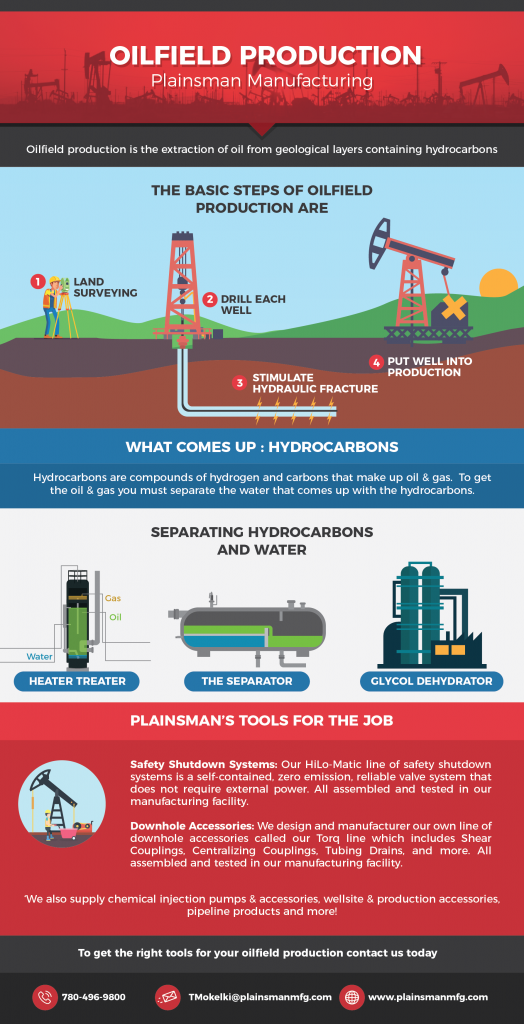

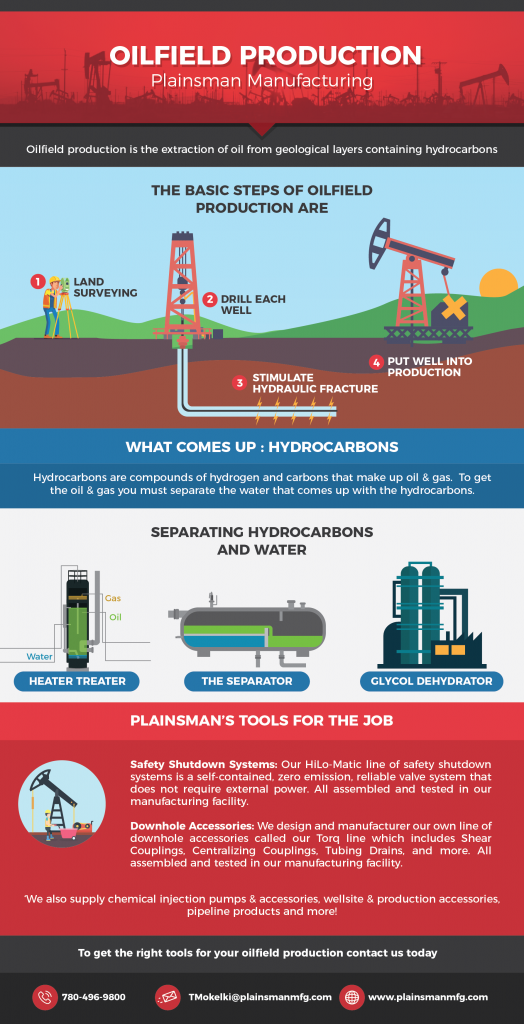

Oilfield production is the extraction of oil from geological layers containing hydrocarbons. Hydrocarbons contain a mixture of oil, water, and gas. The production of hydrocarbons consists of the separation of oil, gas, and water before the oil and gas are taken by pipeline towards a mainland terminal.

The basic steps of oil-field production are:

- A company first surveys the land to determine where to begin drilling, identifies the area to drill, and constructs a drill site. Seismic data is collected with the help of seismic ships and seismic data is interpreted.

- Drill each well: To confirm the interpretation of seismic data, two types of drilling gear are used. Each drill is adopted to a range of water depths. The drilling process takes 2-4 weeks depending on the depth and number of wells that need to be drilled.

- Stimulate hydraulic fracture: After drilling, Hydraulic fracturing is done on the wells. Frack equipment is rigged up, tested, and then fracking begins. This process can take 1-3 months depending on the geology of the area, number of stages per well heads, and type of frack operation.

- Put the well into production: To begin the production process, battery tanks and separators are brought in to be set up. To get the product to the refinery, the product is either piped out into a pipeline or trucks are sent to locations to load and transport that material to the well site to the refinery. A well can produce 20 years or even longer.

What is brought to the surface when drilling for oil and gas is a mixture of fluids and gases, in addition to the stabilization, separation, storage, dispensation, transportation, taxation, and disposal of those portions of the production.

If the oil field seems promising after drilling, the exploration team drills a second time, so they can refine their knowledge about the characteristic of the field.

The decision to stop drilling a well is made only when the appraisal wells have provided enough information either to give up the exploration or to move on or to envisage future production.

Once the oil is refined, it is preserved in reservoirs. It is ready to be injected by pumping to the gasoduct network for industrial and domestic use or as fuel in power-generating stations.

Generally, drilling takes place vertically along the point of maximum thickness of the geological layer containing hydrocarbons.

An oil or gas field is generated from a source rock—organic matter that is buried in the depths of the earth. Once formed, they climb towards the surface.

Hydrocarbons move around below ground because they are lighter than water and tend to make their way toward the surface of the Earth.

On their way, cap rocks can impede their progress and they accumulate in reservoir rocks. Here, they constitute hydrocarbon fields, which can be identified by interpreting seismic data. The data is obtained with the help of seismic ship.

When hydrocarbons are found and if the pressure is sufficient to allow them to come to the surface naturally, the drillers do a flow check. The oil is allowed to come to the surface during several hours or days through a calibrated hole.

To get oil, you must separate the gas and water. In oilfields, hydrocarbons are separated to make the oil ready for delivery into the midstream. The water that comes out is called produced water.

Removing water from the system as early as possible is important because water can make equipment rust and because you don’t want to pay to transport something that is unnecessary.

Tools commonly used to separate hydrocarbons and water are:

- Heater-treaters: separate production fluids into their gas and liquid components to reduce the volatility of the crude.

- The separator: designed to separate condensed liquid from gas and hydrocarbons from water

- Glycol Dehydrator: a device that counter flows glycol through the produced gas and gas liquids, effectively stripping water molecules along the way.

For the past 50 years, Plainsman has been an industry leader with a solid distribution base which includes oilfield supply stores, PC pump suppliers, OEM’s, chemical pump and instrumentation companies, and utility companies in Western Canada.

Our wellsite and production products include a line of red iron products, rod rotators, polished rod clamps, stuffing boxes, blow out preventers, flow tees, adjustable chokes and back pressure regulators.

Our pipeline products include tracer wire, stac wrap and tape, repair clamps and sleeve couplings, polyethylene and steel band casing insulators, and end seals.

We manufacture and distribute products for oilfield production, pipeline maintenance, construction and gas and water distribution.

We are able to respond efficiently to the customer and industry needs because we have an in-house engineering department and a full-service manufacturing facility.